Have any questions?

robin@pro-trueview.com

0086-18007322239

Kinematic Viscometer(135℃)

Summary The instrument is designed and made as per the national standard of Peoples Republic of China GB/T1841 and ASTM D2170 Standard Test Method for Viscosity of Polyolefin Resin Solution. It is used to determine the viscosity of decahydr...

Summary

The instrument is designed and made as per the national standard of People’s Republic of China GB/T1841 and ASTM D2170 Standard Test Method for Viscosity of Polyolefin Resin Solution. It is used to determine the viscosity of decahydronaphthalene solution of polythene and polypropylene at the stipulated temperature. The instrument can also be used to determine the viscosity of asphalt at the stipulated temperature as per the industrial standard of People’s Republic of China T0619 Asphalt Kinematic Viscosity Test (Capillary Viscometer Method).

I. Main technical features

1. High precision digital temperature controller. Electric stirring motor.

2. High temperature resistant glass bath. Double layer structure.

3. Desktop structure. All-in-one design.

4. The maximum heating temperature is 135℃.

II. Main technical specifications

1. Power supply: AC 220 V±10%, 50 Hz

2. Heating power: Two grades; 1000 W (Auxiliary heating) + 600 W (Temperature control)

3. Temperature range: Ambient to 135.0℃

4. Temperature control accuracy: ±0.1℃

5. Mercury thermometer: Rod type; scale division is 0.1 ℃; Temperature range is 100℃~150℃;

6. Bath capacity: about 23 L

7. Sample quantity: You can make determination using 3 capillary viscometers at a time.

8. Stirring motor

(1) Power: 6W

(2) Speed: 1200 RPM

9. Ambient temperature: -10℃~+35℃

10. Relative humidity: <85%

11. Temperature sensor: Platinum resistance; Pt100

12. Maximum power consumption: 1800 W

13. Capillary viscometer: One group of Cannon-Fenske Reverse Flow capillary viscometers; 7 pieces in total. They are

N0.200, 300, 350, 450, 500 and 600 (The inner diameters of R tube of them are 1.02, 1.26, 1.48, 1.88, 2.20, 3.10 and

4.00 mm respectively).

14. Overall dimension: 530mm×400mm×670mm(Bath is included)

The instrument is designed and made as per the national standard of People’s Republic of China GB/T1841 and ASTM D2170 Standard Test Method for Viscosity of Polyolefin Resin Solution. It is used to determine the viscosity of decahydronaphthalene solution of polythene and polypropylene at the stipulated temperature. The instrument can also be used to determine the viscosity of asphalt at the stipulated temperature as per the industrial standard of People’s Republic of China T0619 Asphalt Kinematic Viscosity Test (Capillary Viscometer Method).

I. Main technical features

1. High precision digital temperature controller. Electric stirring motor.

2. High temperature resistant glass bath. Double layer structure.

3. Desktop structure. All-in-one design.

4. The maximum heating temperature is 135℃.

II. Main technical specifications

1. Power supply: AC 220 V±10%, 50 Hz

2. Heating power: Two grades; 1000 W (Auxiliary heating) + 600 W (Temperature control)

3. Temperature range: Ambient to 135.0℃

4. Temperature control accuracy: ±0.1℃

5. Mercury thermometer: Rod type; scale division is 0.1 ℃; Temperature range is 100℃~150℃;

6. Bath capacity: about 23 L

7. Sample quantity: You can make determination using 3 capillary viscometers at a time.

8. Stirring motor

(1) Power: 6W

(2) Speed: 1200 RPM

9. Ambient temperature: -10℃~+35℃

10. Relative humidity: <85%

11. Temperature sensor: Platinum resistance; Pt100

12. Maximum power consumption: 1800 W

13. Capillary viscometer: One group of Cannon-Fenske Reverse Flow capillary viscometers; 7 pieces in total. They are

N0.200, 300, 350, 450, 500 and 600 (The inner diameters of R tube of them are 1.02, 1.26, 1.48, 1.88, 2.20, 3.10 and

4.00 mm respectively).

14. Overall dimension: 530mm×400mm×670mm(Bath is included)

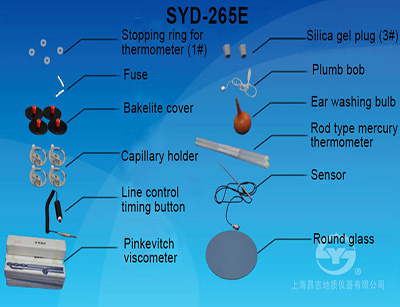

ISYD-265E Kinematic Viscometer Accessories and Documents List

| No. | Name | Unit | Qty | Memo |

| 1 |

SYD-265E Kinematic Viscometer (Including glass inside and outside cylinderstirring devicerubber ring etc.) |

Set | 1 | High temperature 135℃ |

| 2 |

Capillary viscometer (Pinkevitch Viscometer Cannon-Fenske Routine ViscometerStandard Ubbelohde Viscometer) |

Group |

1 | Capillary viscometer characteristicsspecificationquantity according to business agreement |

| 3 |

Mercury thermometer (100~150℃ scale division is 0.1℃) |

Piece | 1 | |

| 4 | Weight ball | Piece | 1 | |

| 5 | Sensor | Piece | 1 | |

| 6 | Bakelite cover | Piece | 4 | |

| 7 | Stopping ring for thermometer (1#) | Piece | 2 | |

| 8 | Capillary viscometer holder | Piece | 4 | |

| 9 | Silica gel stopper (3#) | Piece | 2 | |

| 10 | Fuse 10A(Ф6×30) | Piece | 4 | |

| 11 | Round glass | Piece | 1 | |

| 12 | Wire control timer(Plug in when using by clients) | Piece | 1 | |

| 13 | Washing ear ball | Piece | 1 | |

| 14 | Operation manual | Piece | 1 | |

| 15 | Temperature contrl device usage manual | Piece | 1 | |

| 16 | Quality certificate | Piece | 1 | |

| 17 | Product warranty card | Piece | 1 |

IISYD-265E Kinematic Viscometer's Reagent and Auxiliary Equipments

| No. | Name | Specification | Quantity | Memo |

| 1 | Glycerol or silicone oil | Open flash point >215℃ | 20L | When test temperature above 180℃using silicone oil |

| 2 | Petroleum solution | 1L | 1L/bucket | Trichloro ethylene.gasolinekerosenechoose one only |

| 3 | Distilled water | Three grade | 1 litre | |

| 4 | Washing ear ball | 1 piece |

Notes:

1、The reagent and equipments for installing the instrument are supplied by end-users themselves.

2、The usagemanagement and saving of poisonous and harmful reagentpls operate according to the relative principle.

3、PLS read the operation manual and industry standard before using the instrument.