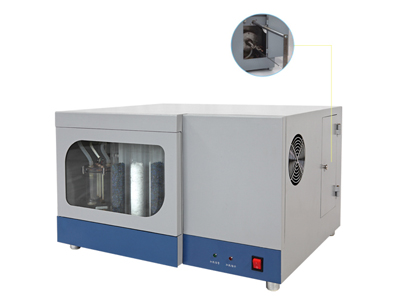

Integrated Sulfur Analyzer

Application area: It is applicable in the industry such as electrical power, coal, commerce inspection, environment protection, metallurgy, paper making, petrochemical, earth probe, and the research institution or quality inspecting organ...

Application area:

It is applicable in the industry such as electrical power, coal, commerce inspection, environment protection, metallurgy, paper making, petrochemical, earth probe, and the research institution or quality inspecting organization to measure the sulfur content in the materials of coal, cinder, coke, catalyst, minerals, rock, and petrochemicals.

Technical parameters:

Furnace temperature: 1150 ℃ (coal), 900 ℃ (oil)

Temperature Uniformity: ± 5 ℃

Sulfur testing resolution: 0.001 %

Sulfur testing range: > 0.01 %

Testing time: 5 min per sample

Sample weight: 45mg~100mg

Power Supply: 220V, 50/60HZ

Power: ≤3kw

Dimension: 620mm× 500mm× 370 mm

Weight: 52kg

Features:

1. Adopting the integrated configuration, put the sample feeding device, electrical scale, vertical high temperature cracking furnace, electrolytic cell, stirrer, and gas purification system in a single container. Thus to make the instrument concise and graceful.

2. Testing time, normally about 5 minutes, can be automatically judged according to the different samples. System errors can be automatically corrected by software and the testing results is more accurate than ASTM (National Standard). Testing with the principle of coulometry, the testing time is shorter than Escar method and high temperature burn moderate method.

3. Using the PID temperature controlling algorithm, hence the temperature control is more accurate and the temperature rise more quickly. Using contactless switches. Have overtemperature protection and electrolyte anti-backflow facility, thus to make the system safe and reliable.

4. Adopting the multi-spots dynamic coefficient correcting method, the system error can be automatically corrected by software, hence to make the testing result more accurate.

5. Temperature control, sample feeding, electrolyzing, and calculation are done by the procedure. System automatically store testing results and print out. Using the dynamic windows operating interface, the operation is simple and easy.

6. Adopting the advanced PCI/USB technology, one computer can control several instruments. And the synthesized instrument can be composed combined with other instruments.

7. Completely support Windows systems; high stability; can link electronic scale and share data in long distance through network.