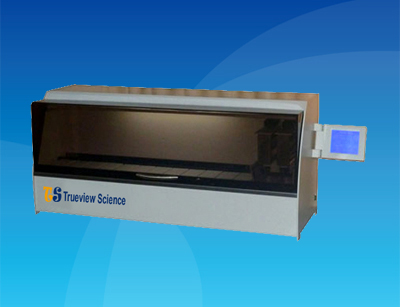

Fully Automated Tissue Processor

Features: ◆Flexible transmission system low noise wear-resistant ◆Imported high-quality parts high-precision positioning system smooth operation ergonomic design ◆Two sets of operation mechanisms doubles the processing capacity. T...

Features:

◆Flexible transmission system, low noise, wear-resistant

◆Imported high-quality parts, high-precision positioning system smooth operation, ergonomic design

◆Two sets of operation mechanisms doubles the processing capacity. Tissue specimens can be separately placed into

different baskets according to size, texture, and origin, thus improving processing performance

Optional single-mechanism mode for processing a smaller number of tissue specimens to ease the operation

◆20 editable programs for each of A and B can be stored in the system

◆Integrated high-quality LCD screen with intuitive bilingual (Chinese/English) software offers clear display and simple

operation; window-scrolling/flipping human-machine conversation interface provides clear instructions for each step

(online help)

◆Fully intelligent design, enabling timely determination and automatic recovery from an abnormal event

◆Real-time visual simulation with icons displays working status dynamically, clearly and intuitively

◆Green inner-cycling air purification system to highly efficiently adsorb and remove poisonous gas; well-sealed gas-

effluxion mechanism to effectively improve the operational environment

◆This system can be automatically started at any time as programmed (Setting Range 0-99 hours and 0-59 minutes)

Processing duration is automatically calculated and displayed on the screen, allowing the user to make a more efficient

work plan

◆Automated fan control: Stays ‘on’ all the time when the specimens are not submerged in cup and 10 seconds every

minute when the specimens are submerged in cup and in processing

◆Automated light control:

stays ‘on’ all the time during programming;

stays ‘off’ during the automatic operation and can be automatically turned ‘on’ anytime by touching the screen or any

key and stays ‘on’ for 2 minutes.

◆Internal dry heating mechanism and triple protection channels offer high-precision automatic gradient temperature

control

Automatically determines the time of heating, thus increasing energy efficiency.

◆Low-energy-consuming control circuit with power protection function

When power outage occurs, the screen displays as normal with a scrolling bar demonstrating the ‘on’ status of the

power protection system.

Battery backup with more than 30 hours of running power

◆Power Protection Station: Station 7 for A basket and Station 5 for B basket, ensuring continued operation during a power

outage.

◆Manual operation can be conducted anytime during the programmed automatic operation, allowing user to check or

add tissue specimens during the operation

◆200 or more specimens can be processed at the same time

Major Technical Specifications

◆Number of Cups: 14(10 for reagents, and the cups at the 11th, 12th, 13th, and 14thstations are used for paraffin

melting);

◆Number of baskets:2

◆Capacity of Each Cup: 1500ml

◆Temperature range:: RT - 800C

◆Temperature Control Precision: ±10C

◆Length of Processing Time in the Cup

Any length between 0 and 99 hours for the 1st and 2nd cup

Any length between 0 and 24 hours for the 3nd to 14th cup

◆Dripping Time: Adjustable within 10s - 60s; shake/drip above cup

◆Frequency of Agitation: Adjustable within 0 - 6 times/minute

◆Working Voltage: AC220V±10%50HZ (standard model); AC110V±10% 60HZ

◆Power Requirements: 550W

◆Dimensions: 1250×440×495 mm (W×D×H)

◆Weight: 92kg