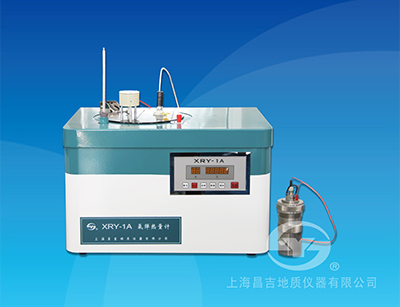

Automatical Oxygen Bomb Calorimeter

Summary The instrument is designed and made as per the National Standard of Peoples Republic of China GB/T213-2008 and ASTM D240 Test Method for Calorific Value of coal GB/T384-1988 Test Method for Calorific Value of Petroleum Products and...

Summary

The instrument is designed and made as per the National Standard of People’s Republic of China GB/T213-2008 and ASTM D240 Test Method for Calorific Value of coal, GB/T384-1988 Test Method for Calorific Value of Petroleum Products and Calibration Regulation of People’s Republic of China JJG672-2001 Oxygen Bomb Calorimeter, as well as Enterprise Standard of Shanghai Q/YXYY 10 XRY Series Oxygen Bomb Calorimeter.

The heat capacity of the instrument is 14000 J/K~15000 J/K, and it is suitable to determine calorific value of combustible materials such as petroleum products without water (gasoline, jet fuels, diesel oil and fuel oils, etc.), coal, coke and paraffin, etc.

I. Main technical features

1. This instrument adopts sealed oxygen bomb. The whole structure adopts stainless steel material. The strength is

enough to resist the max pressure (60~70 atmospheric pressure) when the solid burning. And it can resist the bigger

pressure when liquid fuel burning.

2. The inner water cylinder is composed of stainless steel sheet.The cross section is pyriform and the capacity is 3kg. The

water cylinder is equipped with electric stirrer inside. It ensures the temperature in the water cylinder uniform.

3. The external water jacket is double layer container. It filled with water when doing determination.It make the water

temperature in the cylinder uniform by water jacket stirrer and form the constant temperature environment meeting the

requirements of test.

II. Main technical specifications

1. Heat capacity: 14400 J/K~15000 J/K

2. Resolution: 0.001 K

3. Measurement accuracy: ± 60J/g

4. Repeatability : ≤0.2% (Grade C)

5. Pressure endurance of oxygen bomb: 20 MPa

6. Temperature measurement range: 10 ℃~35 ℃

7. Ambient temperature: 20±5 ℃, the fluctuation is not more than 1 ℃ during one test

8. Data saved: 31 pieces

9. Relative humidity: ≤85%

10. Power supply: AC 220V±5%, 50 Hz

11. Dimension:600mm×460mm×430mm

12.Total power consumption:Less 150W

(Note: Pellet press machine is optional accessory)

| No | Name | Unit | Qty | Remark |

| 1 | Main unit of calorimeter (including oxygen bomb water jacket bucket stirrer and controller of calorimeter) | Set | 1 | |

| 2 | Pellet press machine | Set | 1 | Optional part |

| 3 | Holder of bomb head | Set | 1 | |

| 4 | Seat of oxygen bomb | Set | 1 | |

| 5 | Temperature sensor | Piece | 1 | |

| 6 | Thermometer (0~50 ℃) | Piece | 1 | |

| 7 | Stopper for thermometer (silica gel stopper 2#) | Piece | 1 | |

| 8 | Ignition wire (Φ0.1 nickel-chrome wire) | Meter | 10 | |

| 9 | Crucible | Piece | 2 | |

| 10 | Discharging valve | Piece | 1 | |

| 11 | Oxygen decompression device | Piece | 1 | |

| 12 | Oxygen tube | Pair | 1 | |

| 13 | “O” seal ring (Φ20×2.4 mm) | Piece | 5 | |

| 14 | “O” seal ring (Φ8×1.9 mm) | Piece | 5 | |

| 15 | “O” seal ring (Φ6×1.9 mm) | Piece | 5 | |

| 16 | Seal ring (large “O” ring) | Piece | 2 | |

| 17 | Ignition connection wire | Piece | 1 | |

| 18 | Siphon | Piece | 1 | |

| 19 | Benzoic acid | Piece | 10 | |

| 20 | Stopping ring for thermometer (1#) | Piece | 4 | |

| 21 | Fuse 2 A (Φ5×20) | Piece | 2 | |

| 22 | Operation manual | Piece | 1 | |

| 23 | Quality certificate | Piece | 1 | |

| 24 | Repair guarantee | Piece | 1 | |

| 25 | Operating software CD | Piece | 1 |