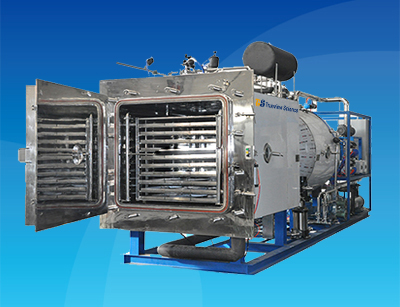

Sterile Preparations CIP+SIP Freeze Dryer

model: TS-SP350

Standard:

E-mail: robin@pro-trueview.com

Description:

TS-SP350 series are widely used in medical field, such as blood products, vaccines, biological products, and chemical medicines, especially western medicine field. This series models are used in many large-scale pharmaceutical factories. In terms of injections, drug quality can be improved and storage time can be extended through freeze drying.

Main features

● The shelves are made with unique patented technology, high pressure resistance, high flatness, and good temperature uniformity.

● The cooling speed can be controlled throught The freeze-drying curve optimization control technology in the pre-frozen phase, and at the same time, the sample heating speed and the current vacuum value also can be controlled in the sublimation and analytical drying stages.

● The patented gas diversion design and control technology ,strong ice collecting capacity and high drying efficiency.

● The unique dual-channel sealing technology of the mobile + fixed dual-channel door seals sterilizes the stationary silicone rubber while steam sterilizing.

● Vacuum adjustment during drying operation to avoid foaming and blowing of special materials and improve drying efficiency.

● Industrial-grade embedded touch screen + dedicated SH-HPSC-IV modular controller, stable and reliable system, high control accuracy.

● The professionally designed LYO-CONTROL control system can save multiple sets of process . At the same time, the process can be adjusted in real time during the drying process to improve the process optimization rate.

● Flexible manual + automatic control mode, the manual for groping process, and the automatic for batch production.

● The powerful LYO-MEGA host computer control system can record and save the operating data, curves and alarm records for ten years to improve the traceability of products; at the same time, it is convenient for observation, operation and fault diagnosis.

● User grades and passwords can be set, and operations can be decentralized to meet GMP-related requirements.

● The non-stardarded can be customized as requested.

Technical parameters

|

models parameters |

unit | TS-SP301 | TS-SP302 | TS-SP303 | TS-SP305 | TS-SP310 | TS-SP315 | TS-SP320 | TS-SP330 | TS-SP350 |

| freeze dryer area | m2 | 1.15 | 2.16 | 3.24 | 5.2 | 10.5 | 15 | 20.2 | 29.7 | 51.3 |

|

shipping weight (thickness 10mm) |

L | 10 | 20 | 30 | 50 | 100 | 150 | 200 | 300 | 500 |

| shelf number | layer | 4+1 | 4+1 | 6+1 | 7+1 | 7+1 | 10+1 | 11+1 | 11+1 | 19+1 |

| shelf dimensions | mm | 600*480 | 600*900 | 600*900 | 750*1000 | 990*1520 | 990*1520 | 1210*1520 | 1500*1800 | 1500*1800 |

| shelf spacing | mm | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 |

| temp. range | ℃ | -50~+70 | -50~+70 | -50~+70 | -50~+70 | -50~+70 | -50~+70 | -50~+70 | -50~+70 | -50~+70 |

| ice collecting capacity | kg/B | ≥20 | ≥40 | ≥60 | ≥100 | ≥300 | ≥300 | ≥400 | ≥600 | ≥1000 |

| cold trap temp. | ℃ | ≤-75 | ≤-75 | ≤-75 | ≤-75 | ≤-75 | ≤-75 | ≤-75 | ≤-75 | ≤-75 |

| cooling mode | - | water cooled | water cooled | water cooled | water cooled | water cooled | water cooled | water cooled | water cooled | water cooled |

| defrosting mode | - | water soaked | water soaked | water soaked | water soaked | water soaked | water soaked | water soaked | water soaked | water soaked |

| ultimate vacuum | pa | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| power | kw | 18 | 21 | 24 | 25 | 58 | 80 | 96 | 120 | 150 |

|

dimenisons (L*W*H) |

m | 2500*1100*2000 | 2500*1300*2000 | 2800*1200*2500 | 4000*1500*2500 | 6700*1800*3500 | 6500×2300×3600 | 7400*2100*3700 | 6500*2400*3800 | 7500*2400*4600 |

| vialsΦ22 | piece | 2460 | 4608 | 6912 | 11648 | 22932 | 34398 | 45045 | 64449 | 111321 |

| vials Φ16 | piece | 4788 | 8960 | 13440 | 22540 | 42966 | 64449 | 84843 | 129789 | 224181 |

| power | kg | 1500 | 2600 | 2800 | 5000 | 7000 | 8000 | 11000 | 15000 | 26000 |

| vapor consumption | kg/h | 60 | 80 | 100 | 130 | 200 | 230 | 280 | 380 | 500 |

| inpouring water volume | l/min | 60 | 75 | 90 | 120 | 160 | 200 | 230 | 280 | 400 |

Applications

a) provided to the pharmaceutical factories

b) Suitable for freeze drying of bulk (liquid, pasty, solid) conventional materials.

b) Suitable for freeze drying of bulk (liquid, pasty, solid) conventional materials.

c) Suitable for freeze drying of camel milk, goat milk, donkey milk, lactic acid bacteria and other substances.