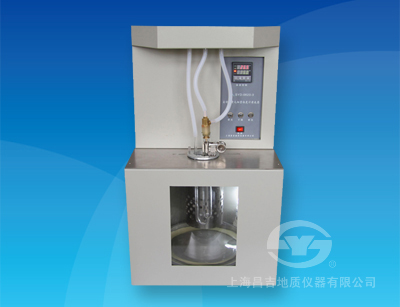

Vacuum Viscometer Tube Washer

model: SYD-0620-3

Standard: ASTM -- D445

E-mail: robin@pro-trueview.com

Summary

This instrument ASTM D445 is designed for cleaning the vacuum capillary viscometer tubes.It is an ideal instrument for cleaning the capillary viscometer tube for testing the asphalt. It can also be used for cleaning two-port counter current glass capillary viscometer, and especially suitable to clean the capillary viscometer tubes for the high- viscosity oils, changing the rely on traditional manual cleaning, time-consuming and laborious and difficult to clean the status.

I. Main technical features

1. It adopts SCM technology, the software program automatic capillary viscometer internal cleaning and drying, to realize

automatic capillary viscometer cleaning.

2. With wide range of application, suitable to all automatic cleaning with two port countercurrent glass capillary viscometer.

3. With 4 cleaning holes, when a group is cleaned, you can heat and protect the temperature of the other three group of

capillary vicometers.

4. With the high automation,reasonable structure and simple operation, it can meet the requirements of the petrochemical,

electric power, railway, commodity inspection, military and scientific research units of bitumen and other petroleum

products glass capillary viscometer cleaning and drying.

II. Main technical specifications

1. The temperature control of water bath: room temperature ~90℃

2.Washing holes: four

3.Environment temperature: room temperature:~35℃

4.Relative temperature: ≤85%

5. Power supply: AC(220±10%)V,50Hz

6. Maximum power consumption: no more than 700W

7. Dimension: 380㎜×380㎜×650㎜(Bottles are not included.)

This instrument ASTM D445 is designed for cleaning the vacuum capillary viscometer tubes.It is an ideal instrument for cleaning the capillary viscometer tube for testing the asphalt. It can also be used for cleaning two-port counter current glass capillary viscometer, and especially suitable to clean the capillary viscometer tubes for the high- viscosity oils, changing the rely on traditional manual cleaning, time-consuming and laborious and difficult to clean the status.

I. Main technical features

1. It adopts SCM technology, the software program automatic capillary viscometer internal cleaning and drying, to realize

automatic capillary viscometer cleaning.

2. With wide range of application, suitable to all automatic cleaning with two port countercurrent glass capillary viscometer.

3. With 4 cleaning holes, when a group is cleaned, you can heat and protect the temperature of the other three group of

capillary vicometers.

4. With the high automation,reasonable structure and simple operation, it can meet the requirements of the petrochemical,

electric power, railway, commodity inspection, military and scientific research units of bitumen and other petroleum

products glass capillary viscometer cleaning and drying.

II. Main technical specifications

1. The temperature control of water bath: room temperature ~90℃

2.Washing holes: four

3.Environment temperature: room temperature:~35℃

4.Relative temperature: ≤85%

5. Power supply: AC(220±10%)V,50Hz

6. Maximum power consumption: no more than 700W

7. Dimension: 380㎜×380㎜×650㎜(Bottles are not included.)