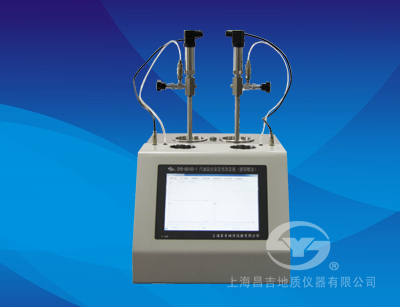

Automatic Gasoline Oxidation Stability Tester

Summary

The instrument is designed and made as per national standard of People’s Republic of China GB/T8018-87 Gasoline - Determination of oxidation stability - Induction period method. It is suitable to determine the oxidation stability of gasoline. It can also be used to do determination as per ASTM D525 Standard Test Method for Oxidation Stability of Gasoline (Induction Period Method)

I. Main technical features

1. Desktop structure,integrated design,the test part and control part united as one,high integration,no external

computer,mouse and key board.

2. Adopting built-in industrial personal computer(IPC),automation work mode,10.1 inch color touch LCD display,Windows

operation system,all English version interface,good outlook and convenient operating.

3. Metal bath. No pollution. No need to adding water.

4.Double holes design to test two samples at the same time.It’s easy to do the parallel test.

5. Well designed heat preservation system. It can save energy as well as prevent operator from scalding.

6. The bomb assembly is unit-body design. It shorts the pressure testing pipe and makes the pressure determination more

accurate. It also guarantees the bomb being well sealed to make the test result more reliable.

7. Color LCD real-time display the two bomb test curve chart, two bombs comparative curve chart,time and pressure etc

relative data.The time of curve graph will be changed automatically according to the real time length of curve,the

maximum 3000 minutes,wide application and direct reading test results.

8.High automatic software design,automatically running,friendly human-machine interface.

9.Oxygen bomb location hole design,it’s convenient for operator to disassemble the cover of oxygen bom in holes,and easy

to put the oxygen bomb during the test.

II. Main technical specifications

1. Power supply: AC220V±10%,50Hz

2. Heating power: Less 1000W, the actual heating power is automatically controlled by computer

3. Measuring range of oxygen bomb pressure transmitter:(0~1600)kPa, accuracy:±2‰

4. Temperature control point of metal bath: 100.0℃±1℃

5. Thermometer: Mercury-in glass thermometer, can correct coefficient as need.

6. Ambient temperature: ≤40℃

7. Relative humidity: ≤85%

8.Outline dimension: 470㎜×380㎜×320㎜(L*W*H without test barrel)

470㎜×380㎜×600㎜(L*W*H with test barrel)