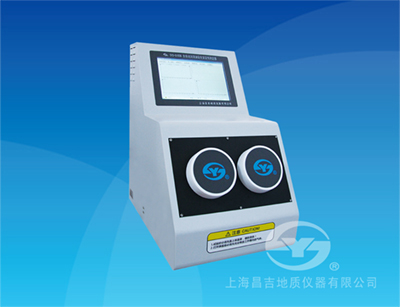

Automatic Lubricating Oils Oxidation Stability Tester

model: SYD-0193B

Standard:

E-mail: robin@pro-trueview.com

Summary

The instrument is designed and made as per ASTM D2272-2009 Standard test Method for Oxidation Stability of Lubricating oil-test method B,the temperature at 50℃ or 140℃,and the standard of People’s Republic of China SH/T 0193 Lubricating oils-Determination of oxidation stability-Rotating pressure vessel method.The instrument is used to determine the oxidation stability of steam turbine with the same composition (oil base oil and additive) .Also can be used to determine new mineral insulating oil containing 2,6-BHT.

I. Main technical features

1. All-in-one design instrument,high level of integration,touch screen,no external computer and keyboard etc.

2. Metal bath design,It eliminate both the lampblack harm to operator and environmental pollution,also simplify the operation.

3.Double holes design,it can test 2 kinds of samples at same time,and is more convenient for operator to make the parallel

test.

4.The rotation of oxidation bomb changed to the flask rotation,It ensures the stable rotating speed of the flash in the cylinder

at (100±1)r/min and without noise.

5.With inner IPC(industrial personal computer),fully automatic work mode,10.1 inch touch screen,English version

interface,unit the test part and the control part as one,desktop structure,easy operation and nice outline.

6.With the cold fan system to shorten the time interval of continuous tests.

7.With the decompression system,it’s convenient to adjust the needed pressure value of the air source,also convenient to

inflate and deflate.

8.With the high precision pressure sensor to detect the inner pressure of the cylinder,the test data is reliable and stable.With

the high precision temperature sensor to automatically detect and control the temperature of the metal bath.

9.The software design is with high degree of automation,It’s sufficient to consider the user’s operating habit and standard

requirements.It could automatically complete a series of operations,and give the relevant operating hints on the interface

to guide the user in doing next operation and avoid the mistake.

II. Main technical specifications

1. Bath temperature control point: 140℃,150℃

2. Temperature accuracy: ±0.1℃

3. Pressure measurement range: (0~1.6)MPa

4. Pressure measurement accuracy: ±2‰

5. Work mode:double metal bath,2 kinds of samples tested at same time or 1 type sample tested

6. Rotation speed: (100±5)r/min

7. Included angle between oxygen bomb and water level: 30°

8. Power supply: AC(220±10%)V,50Hz

9. Total power consumption: <1500W

10. Environment temperature: -10℃ ~40℃

11. Relative humidity: ≤85%

12. Heating tube power: 2500W

13.Dimension:500mm×370mm×540mm(L*W*H)

14.Net weight: About 25Kg

The instrument is designed and made as per ASTM D2272-2009 Standard test Method for Oxidation Stability of Lubricating oil-test method B,the temperature at 50℃ or 140℃,and the standard of People’s Republic of China SH/T 0193 Lubricating oils-Determination of oxidation stability-Rotating pressure vessel method.The instrument is used to determine the oxidation stability of steam turbine with the same composition (oil base oil and additive) .Also can be used to determine new mineral insulating oil containing 2,6-BHT.

I. Main technical features

1. All-in-one design instrument,high level of integration,touch screen,no external computer and keyboard etc.

2. Metal bath design,It eliminate both the lampblack harm to operator and environmental pollution,also simplify the operation.

3.Double holes design,it can test 2 kinds of samples at same time,and is more convenient for operator to make the parallel

test.

4.The rotation of oxidation bomb changed to the flask rotation,It ensures the stable rotating speed of the flash in the cylinder

at (100±1)r/min and without noise.

5.With inner IPC(industrial personal computer),fully automatic work mode,10.1 inch touch screen,English version

interface,unit the test part and the control part as one,desktop structure,easy operation and nice outline.

6.With the cold fan system to shorten the time interval of continuous tests.

7.With the decompression system,it’s convenient to adjust the needed pressure value of the air source,also convenient to

inflate and deflate.

8.With the high precision pressure sensor to detect the inner pressure of the cylinder,the test data is reliable and stable.With

the high precision temperature sensor to automatically detect and control the temperature of the metal bath.

9.The software design is with high degree of automation,It’s sufficient to consider the user’s operating habit and standard

requirements.It could automatically complete a series of operations,and give the relevant operating hints on the interface

to guide the user in doing next operation and avoid the mistake.

II. Main technical specifications

1. Bath temperature control point: 140℃,150℃

2. Temperature accuracy: ±0.1℃

3. Pressure measurement range: (0~1.6)MPa

4. Pressure measurement accuracy: ±2‰

5. Work mode:double metal bath,2 kinds of samples tested at same time or 1 type sample tested

6. Rotation speed: (100±5)r/min

7. Included angle between oxygen bomb and water level: 30°

8. Power supply: AC(220±10%)V,50Hz

9. Total power consumption: <1500W

10. Environment temperature: -10℃ ~40℃

11. Relative humidity: ≤85%

12. Heating tube power: 2500W

13.Dimension:500mm×370mm×540mm(L*W*H)

14.Net weight: About 25Kg