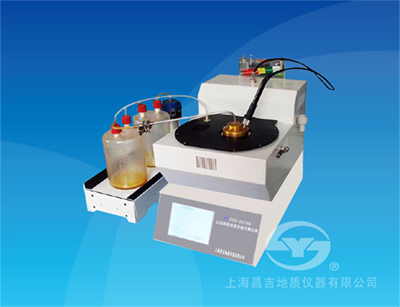

Automatic Lubricating Oil Evaporation Loss Tester(Noack B method)

model: SYD-0059B

Standard:

E-mail: robin@pro-trueview.com

Summary

The Instrument is designed and manufactured according to Industry standard NB/SH/T 0059-2010 and ASTM D5800 Standard test method for evaporation loss of lubricating oils by the Noack B method.It’s suitable to determine lubricating oil(especially internal combustion engine oil) and the evaporation loss of lubricating base oil at 250℃.

I. Main technical features

1. Latest technology:adopt B method to instead of A method,There are no wood alloy in process of test to avoid

environment pollution and personnel injure.

2. Control method:adopting embedded operating system,high speed microprocessor control,work steadily and reliably.

3. Printing way:with USB printer port,RS232 port,realize the connection and communication between printers and

computers.

4. Touching:adopting LCD display,convenient operation by touch screen.

5. Safety:with the inner diagnostic program and many alarms,realize the smart management when instrument’s fault.

6. Precision control:built-in high-capacity EPROM,real-time recording the value of temperature and pressure at each

minutes.

II. Main technical specifications

1. Temperature control:room temperature to 300℃

2. Temperature resolution:resolution accuracy ±0.1℃

3. Temperature control accuracy: ±0.5℃

4. Heating unit:environment protection light heating unit

5. Vacuum control:vacuum pump and pressure meter air filter

6. Pressure range: 0~25mm H2O

7. Pressure accuracy:resolution accuracy ±0.05 mm H2O

8. Stability precision: ±0.2 mm H2O

9. Total consumption: less 2200W(heating power 2000W)

10. Environment temperature: ≤30℃

11. Relative humidity: ≤85%

12. Power supply: AC220V±10%,50Hz

13. Outline dimension:

main uint 550㎜×360㎜×360㎜

toolbox: 330㎜×210㎜×80㎜

(L*W*H,buit-in 2pcs 2500ml voltage stabilization bottle)

The Instrument is designed and manufactured according to Industry standard NB/SH/T 0059-2010 and ASTM D5800 Standard test method for evaporation loss of lubricating oils by the Noack B method.It’s suitable to determine lubricating oil(especially internal combustion engine oil) and the evaporation loss of lubricating base oil at 250℃.

I. Main technical features

1. Latest technology:adopt B method to instead of A method,There are no wood alloy in process of test to avoid

environment pollution and personnel injure.

2. Control method:adopting embedded operating system,high speed microprocessor control,work steadily and reliably.

3. Printing way:with USB printer port,RS232 port,realize the connection and communication between printers and

computers.

4. Touching:adopting LCD display,convenient operation by touch screen.

5. Safety:with the inner diagnostic program and many alarms,realize the smart management when instrument’s fault.

6. Precision control:built-in high-capacity EPROM,real-time recording the value of temperature and pressure at each

minutes.

II. Main technical specifications

1. Temperature control:room temperature to 300℃

2. Temperature resolution:resolution accuracy ±0.1℃

3. Temperature control accuracy: ±0.5℃

4. Heating unit:environment protection light heating unit

5. Vacuum control:vacuum pump and pressure meter air filter

6. Pressure range: 0~25mm H2O

7. Pressure accuracy:resolution accuracy ±0.05 mm H2O

8. Stability precision: ±0.2 mm H2O

9. Total consumption: less 2200W(heating power 2000W)

10. Environment temperature: ≤30℃

11. Relative humidity: ≤85%

12. Power supply: AC220V±10%,50Hz

13. Outline dimension:

main uint 550㎜×360㎜×360㎜

toolbox: 330㎜×210㎜×80㎜

(L*W*H,buit-in 2pcs 2500ml voltage stabilization bottle)