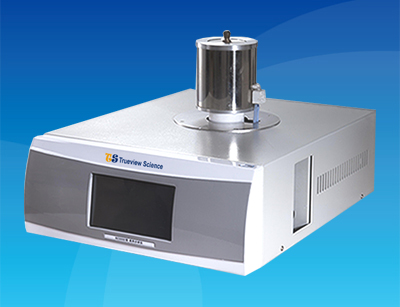

Differential thermal analyzer

Introduction:

DTA:Differential Thermal Analysis is a technique which can measure the temperature difference and temperature relationship between the sample and the reference material in the process control temperature. Differential thermal analysis curves can describe the relationship of the temperature difference △T changes with the temperature or time between the sample and the reference material. During the DTA experiment, the sample temperature changes due to the endothermic or exothermic effect of the phase transition or reaction. Such as, phase transition, melting, crystalline structure transition, boiling, sublimation and evaporation, dehydrogenation, cleavage reaction or decomposition reaction, oxidation or reduction reaction, the destruction of lattice structure and the other chemical reaction.

Technical parameters:

1. The temperature range: room temperature ~ 1150 ℃

2. measuring range: 0~±2000μV

3. DTA precision: ±0.1μV

4. Heating rate: 1 ~ 80℃/min

5. Temperature resolution: 0.1℃

6. Temperature accuracy: ±0.1℃

7. Temperature repeatability: ±0.1℃

8. Temperature control:

Warming temperature: program control

(User can adjust parameters according to requirements)

Cooling temperature: air-cooled program control

Constant temperature: program control (User can set the time arbitrarily)

9. Body Structure: Use the structure of the cover to replace the traditional lifting furnace, with high precision and easy operation.

10. Atmosphere control: (optional) gas flow meter, atmosphere conversion device

11. Data interface: standard USB connector, supporting data line and operating software

12. Display: 24 bit color 7 inch LCD touch screen display

13. Parameters of Standard: Equipped with reference substances, with a key calibration fuction (User can correct the temperature)

14. Baseline adjustment: Users can adjust the baseline by changing baseline slope and intercept

15. Work power: AC 220V 50Hz